When selecting a junction box for electrical or industrial applications, one of the most critical factors to consider is its IP (Ingress Protection) rating. This rating determines how well the enclosure protects against dust, water, and other foreign objects.

Understanding IP ratings is essential for ensuring safety, durability, and compliance with industry standards. In this guide, we’ll explain:

- What an IP rating is and how it’s structured

- The difference between dustproof and waterproof ratings

- Common IP ratings for junction boxes and their applications

- How to choose the right IP-rated junction box for your needs

- By the end, you’ll know exactly which IP rating is best for your project.

What Is an IP Rating?

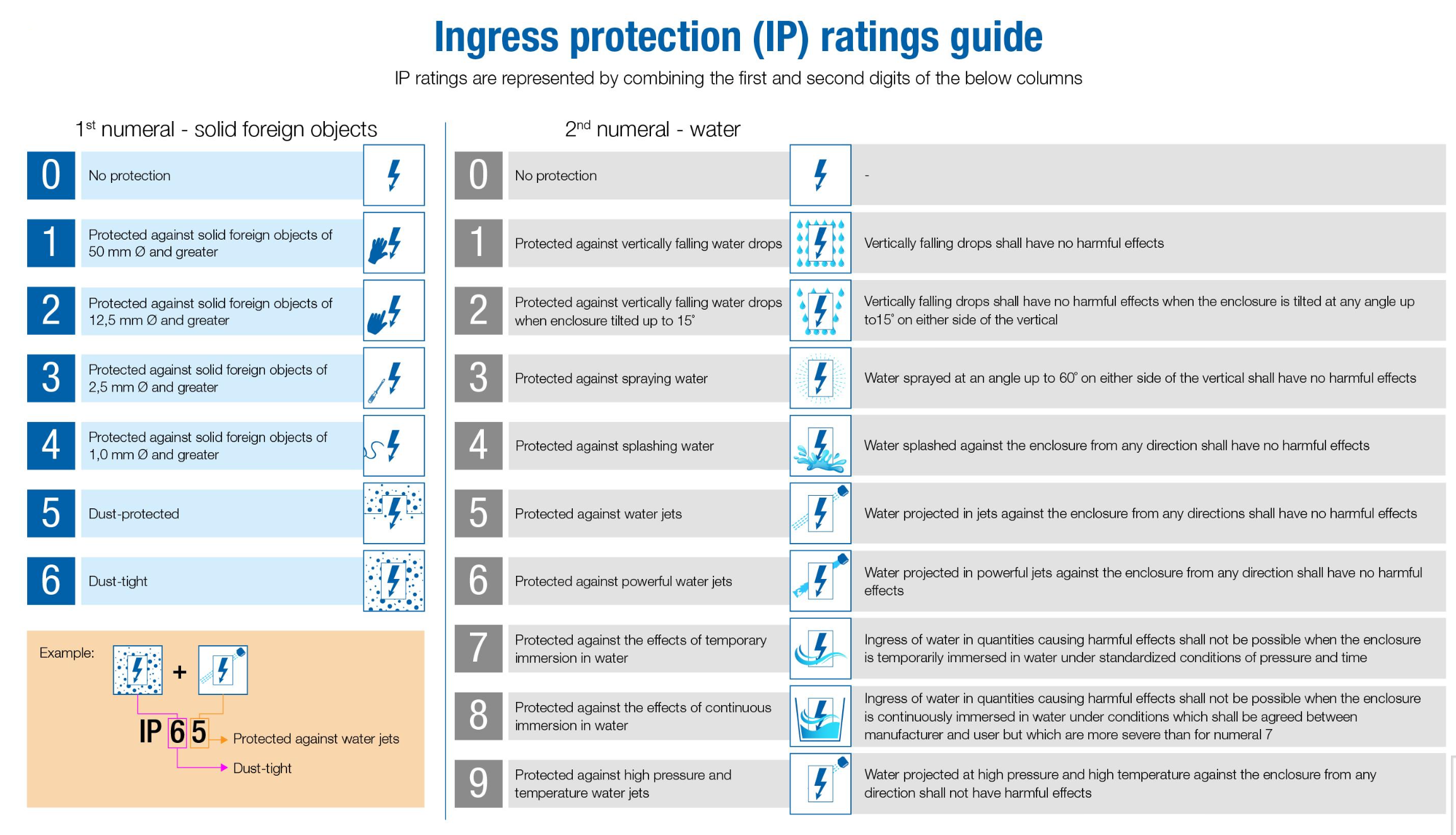

An IP rating (Ingress Protection rating) is an international standard (defined by IEC 60529) that classifies the level of protection an electrical enclosure provides against solids and liquids.

The rating consists of two digits:

First digit (0-6) – Protection against solid objects (dust, debris, tools)

Second digit (0-9) – Protection against liquids (water, moisture, sprays)

For example, an IP65-rated junction box is dust-tight (6) and protected against low-pressure water jets (5).

Breaking Down IP Rating Numbers

- First Digit: Protection Against Solids

The initial digit quantifies the enclosure’s safeguard capabilities, specifically its effectiveness in preventing unauthorized access to hazardous components such as live electrical conductors and rotating parts, as well as in repelling the intrusion of solid foreign matter.

| Digit | Protection Level | Description |

| 0 | No protection | No protection against contact or dust. |

| 1 | >50mm objects | Protects against large body parts (e.g., hands). |

| 2 | >12.5mm objects | Protects against fingers and small tools. |

| 3 | >2.5mm objects | Protects against wires and thick tools. |

| 4 | >1mm objects | Protects against most wires and small screws. |

| 5 | Dust-protected | Limited dust ingress (not fully dust-tight). |

| 6 | Dust-tight | No dust entry; complete protection. |

- Second Digit: Protection Against Liquids

The second digit defines the extent to which the enclosure safeguards against the detrimental intrusion of water.

| Digit | Protection Level | Description |

| 0 | No protection | Low-pressure water jets (6.3mm nozzle). |

| 1 | Dripping water | Vertical drops (condensation). |

| 2 | Dripping (15° tilt) | Water at a 15° angle. |

| 3 | Spraying water | Rain or light splashes (up to 60°). |

| 4 | Splashing water | Water from any direction (limited ingress). |

| 5 | Water jets | Low-pressure water jets (6.3mm nozzle). |

| 6 | Powerful water jets | High-pressure water (12.5mm nozzle). |

| 7 | Immersion (1m, 30min) | Temporary submersion. |

| 8 | Continuous immersion | Long-term underwater use. |

| 9K | High-pressure, high-temp washdown | Steam cleaning, industrial use. |

Common IP Ratings for Junction Boxes

Here are the most widely used IP ratings for junction boxes and their best applications:

| IP20 | Protection: Solids >12.5mm, no water protection. Use Case: Indoor electrical enclosures (dry environments). |

| IP44 | Protection: >1mm solids + splashing water. Use Case: Damp indoor areas (e.g., bathrooms, kitchens). |

| IP54 | Protection: Dust-protected + splashing water. Use Case: Workshops, garages, light outdoor use. |

| IP65 | Protection: Dust-tight + low-pressure water jets. Use Case: Outdoor junction boxes, industrial settings. |

| IP66 | Protection: Dust-tight + powerful water jets. Use Case: Harsh outdoor environments (construction sites). |

| IP67 | Protection: Dust-tight + temporary immersion (1m, 30min). Use Case: Underground cabling, marine applications. |

| IP68 | Protection: Dust-tight + continuous underwater use. Use Case: Submerged electrical systems, deep outdoor installations. |

| IP69K | Protection: Dust-tight + high-pressure, high-temperature washdown. Use Case: Food processing, chemical plants, heavy industry. |

How to Choose the Right IP-Rated Junction Box

When selecting a junction box, consider:

✅ Environment – Will it be indoors, outdoors, or submerged?

✅ Exposure to Dust/Debris – Does it need full dust protection (IP6X)?

✅ Water Contact – Will it face rain, jets, or submersion?

✅ Industry Standards – Does your application require specific certifications?

Example Choices:

Indoor control panel? → IP20 or IP44

Outdoor lighting? → IP65 or IP66

Industrial washdown area? → IP69K

Conclusion: Why IP Ratings Matter for Junction Boxes

Choosing the right IP-rated junction box ensures long-term safety, prevents electrical hazards, and complies with industry regulations. Whether you need basic indoor protection (IP20) or extreme durability (IP69K), understanding IP codes helps you make the best decision.

Looking for high-quality IP-rated junction boxes? Browse our selection to find the perfect enclosure for your project.https://shjianye.com/product-2/

FAQ

Q: Is IP68 better than IP65?

A: Yes, IP68 offers full dust protection and continuous waterproofing, while IP65 is only dust-tight and resistant to water jets.

Q: Can an IP66 junction box be submerged?

A: No, IP66 resists powerful jets but isn’t designed for submersion—use IP67 or IP68 instead.

Q: What’s the difference between IP44 and IP54?

A: IP54 provides better dust protection, making it suitable for dustier environments.